- Who's

-

-

WHO’S

WHO’S

Inside the homes and beauty cabinets of inspiring and influential people

-

-

-

-

- ModelsBeauty tips and makeup tutorials from top models.

- CreativesHow to apply makeup like a makeup artist, the latest hairstyles from our favourite hair stylists and the latest beauty tips from the top beauty therapists.

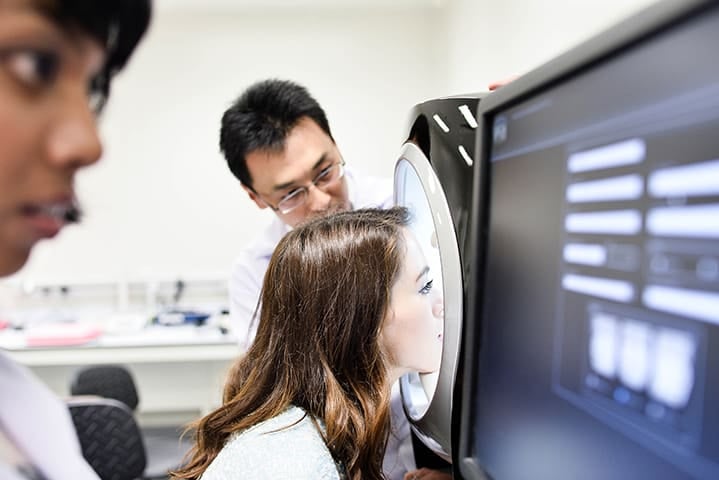

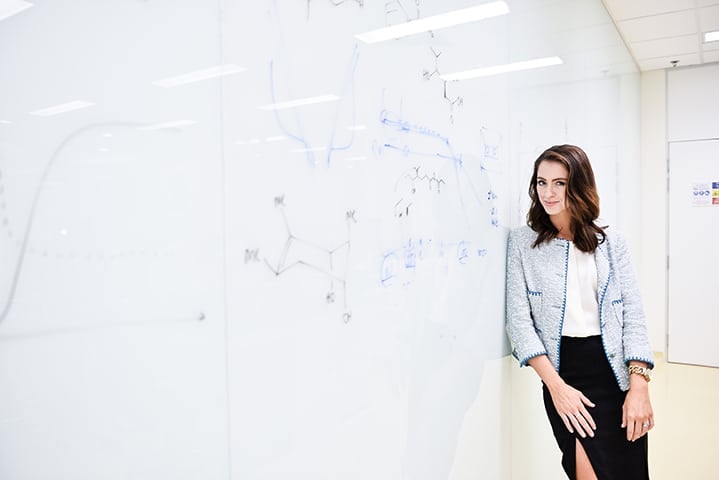

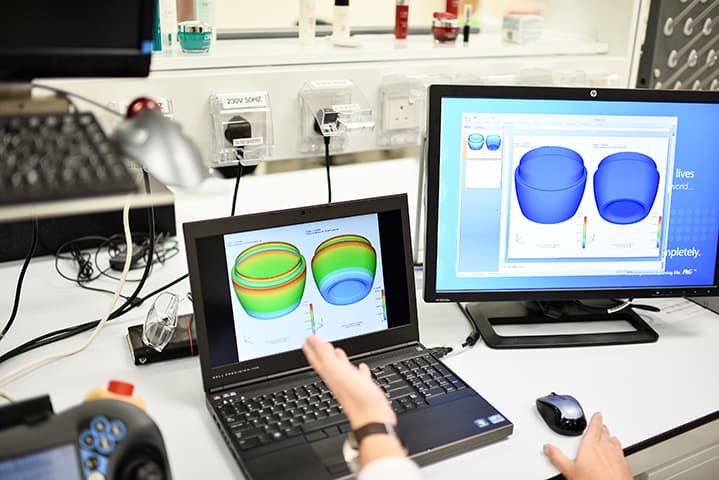

- EntrepreneursHow to start a beauty business and more. Beauty company founders share their must-have products alongside inspiring stories of how they made it.

- InfluencersBeauty tips and makeup tutorials from the biggest bloggers, vloggers, Instagrammers and website founders.

- Actors & Presenters

-

-

- How-Tos

-

-

HOW-TOS

HOW-TOS

Educate your beauty routine with expert tips, tricks and tutorials

-

-

-

-

-

- Go-Tos

- Vodcast

- Travel

- Interiors

- Sigourney's Edit

- About